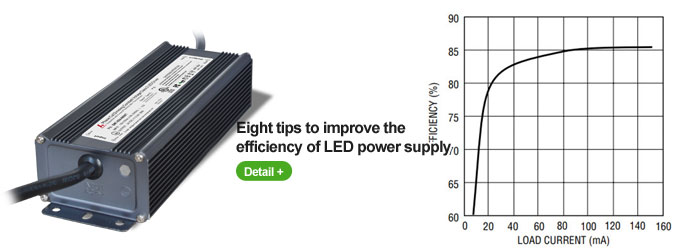

Eight tips to improve the efficiency of LED power supply

1. The main current loop PCB should be as short as possible.

LAYPCB experience, and layout, this is nothing, the quick way is to look at the works of big factories.

2. Optimize the design of 300w LED transformer parameters to reduce eddy current loss caused by ringing.

This is more difficult. First, you must master the basic knowledge of electromagnetics and design a reasonable transformer. The most important thing is patience. Even if you think of improving the efficiency by 0.5%, you must try.

3. Reasonably select switching devices.

This is the balance between cost and performance. What kind of customer requirements and what kind of devices are used, but it must be reasonable. If you want efficiency, there is no doubt that COOL MOS, low VF output diode

4. Input EMI part optimization design

If you have passed the safety regulations, this part is more sophisticated, mainly because of experience.

5. Choose a highly efficient topology structure

This is the beginning of the program selection, such as PWM dimmable led power supply and QR PFM. At present, when customers put forward efficiency requirements, it is necessary to evaluate which topology to choose

6. Choose a good electrolytic capacitor

Many people ignore this. The loss of electrolysis is very large. There is a detailed explanation in an article by Mr. Chen Yongzhen

7. Start part power consumption design

On the premise of efficiency, it must be considered. At present, many chips have HV startup pins, and the startup current is getting lower and lower. This is to know more about new devices. Of course, there are additional circuits for lossless startup. I think Not suitable for LED driver.

8. Chip auxiliary power supply optimization

At this point, ST’s L6562D application document pointed out that 15V is the best, but LEDs generally have a wide voltage output, so my choice is to add a linear regulator to make the chip work at 15V to reduce loss.