FAQ of Scanning Electron Microscope (SEM)

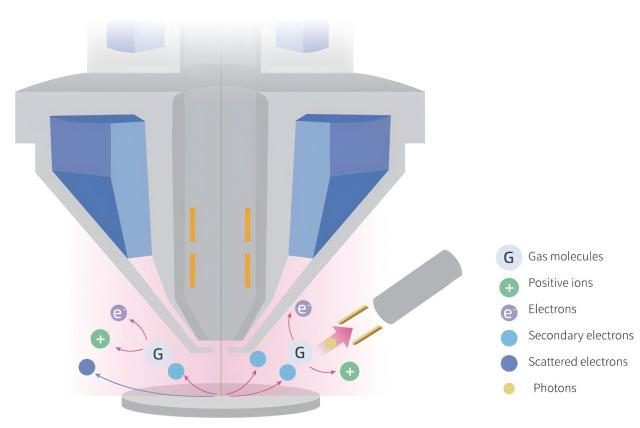

The principle of a Scanning Electron Microscope (SEM) involves the emission of an electron beam from an electron gun, which is accelerated by an electric field.

The electron beam scans the specimen surface line by line, exciting the specimen to produce various physical signals. These signals are collected by detectors and converted into video signals in sequential and proportional order.

By detecting a specific signal, amplifying the video signal, and signal processing, a scanning image reflecting the surface features of the specimen is obtained on the display screen.

Common Issues:

1. Does the magnetic nature of a specimen affect SEM testing?

a. Magnetic Field Interference: The electron beam in SEM is focused by electromagnetic lenses. Magnetic elements in the specimen may generate a magnetic field that interferes with the path of the electron beam, resulting in image distortion or reduced resolution.

b. Signal Detection: SEM forms images by detecting Secondary Electrons, Back-Scattered Electrons, and other signals resulting from the interaction between electrons and the specimen. If the specimen contains magnetic elements, these elements may affect electron scattering and detection, which can impact the image quality and accuracy of the compositional analysis.

c. Specimen Preparation: specimens containing magnetic elements may present challenges during preparation, as these elements may adhere to other magnetic surfaces. Therefore, special specimen preparation techniques may be required to ensure specimen stability and representativeness.

d. Compositional Analysis: During Energy Dispersive Spectrometer (EDS) analysis, if the specimen contains magnetic elements, their magnetic fields may alter the path of X-rays, potentially affecting the detection of X-rays.

e. Heating Effects: In certain cases, the interaction between the electron beam and the specimen may generate heat. If the specimen contains magnetic elements, this heating may cause local magnetic changes in the specimen, which can affect the results of SEM analysis.

2. What are the effects of radioactive specimens on SEM testing?

a. Specimen Stability: Radioactive decay processes can cause changes in the structure of the specimen, affecting the stability and reproducibility of the analysis results.

b. Specimen Heating: Radioactive decay may generate heat, leading to localized or overall heating of the specimen, which can influence the microstructure of the specimen and the interaction with the electron beam.

c. Signal Interference: Radioactive specimens may emit alpha particles, beta particles, or gamma rays, which can interfere with the detectors in SEM, resulting in increased image noise and degraded imaging quality.

d. Charge Accumulation: Charged particles emitted by radioactive specimens may accumulate charges on the specimen surface or in the vicinity, which can affect electron beam focusing and scanning, thereby impacting image resolution and contrast.

e. Detector Damage: Radioactive radiation can potentially damage the detectors used for detecting secondary electrons and back-scattered electrons in SEM, reducing their performance and lifespan.

f. Analysis Interference: If the SEM is equipped with Energy Dispersive Spectrometer (EDS) or other analysis tools, radioactive radiation may interfere with X-ray detection, leading to inaccurate results.

3. Is specimen stability important for SEM testing?

Specimen stability is crucial for SEM testing under a high vacuum environment and intense electron beam irradiation. The high-energy electron beam may cause certain specimens to evaporate or sublime, especially for organic materials or certain volatile elements. Additionally, the electron beam can induce heating effects, leading to structural deformation or chemical changes in the specimen, which may affect the observed microstructure.

Therefore, appropriate pre-processing and protection measures, such as using low-voltage scanning or cooling stage techniques, are needed for sensitive specimens.

4. Why can’t Energy Dispersive Spectrometer (EDS) in SEM provide accurate quantification?

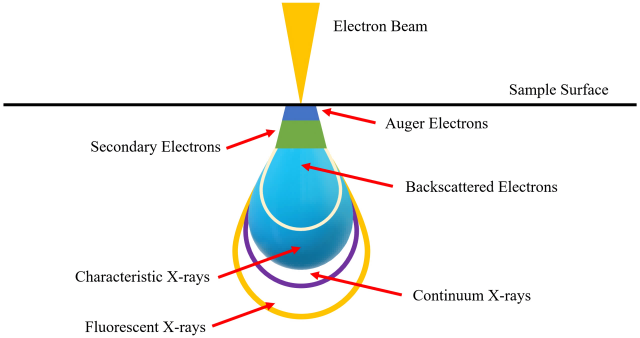

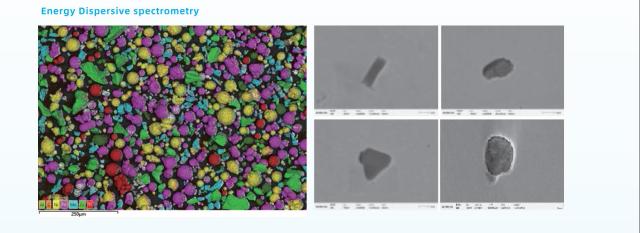

EDS combined with Scanning Electron Microscopy allows for elemental analysis of materials in micro-areas. The principle is based on the fact that each element has its characteristic X-ray wavelength, which depends on the characteristic energy released during the energy level transition.

The accuracy of quantitative EDS analysis depends on various factors, including the specimen preparation process, specimen conductivity, elemental content, and atomic number.

Both principle-based errors (such as databases and standards) and human factors can contribute to inaccuracies in quantitative analysis.

5. What is a back–scattered electron image?

Back-scattered Electrons (BSE) are electrons that are scattered in the specimen and then emitted from the top surface. They reflect the differences in surface orientation and average atomic weight of the specimen.

The formation of a back-scattered electron image is due to the regions on the specimen surface with a higher average atomic number appearing brighter, generating stronger back-scattered electron signals.

Conversely, regions with a lower average atomic number produce fewer back-scattered electrons, resulting in darker areas on the fluorescent screen or photograph, thereby creating atomic number contrast.

6. What is the relationship between the scale bar in electron microscope images and the magnification?

The scale bar in electron microscope images can either be fixed or variable. In the former case, the length of the scale bar remains constant, but the represented length changes with the magnification.

In the latter case, the length of the scale bar can be adjusted to accommodate different stages of magnification, while the represented length remains fixed within a certain magnification range.

Therefore, the numerical value of the scale bar does not have a direct relationship with the magnification. It depends on the settings of different instrument manufacturers.

7. Why is it necessary to coat non-conductive or poorly conductive specimens with gold, carbon, or platinum?

Non-conductive specimens, such as plastics, glass, or biological tissues, tend to accumulate electric charges when observed in SEM, leading to image distortion.

To eliminate this charging effect, the specimen surface is typically coated with a thin metal film, such as gold, platinum, or carbon. This thin film provides adequate conductivity without significantly affecting the microstructure and composition of the specimen.

Coating with gold is a commonly used specimen preparation technique that improves imaging quality and provides additional specimen information.

8. Does gold coating affect the morphology of the specimen?

After gold coating, the specimen surface is covered with only a few atomic layers of gold, with a few nanometers thickness to a dozen nanometers. This coating has almost no effect on the specimen’s morphology.